Self Leveling Epoxy Flooring

Self Leveling Epoxy Flooring Specification

- Hard dry time

- 24 hours at 25C

- State

- Liquid (before application), Solid (after curing)

- Solid Content

- 98% 2%

- Service Period

- 510 Years (depending on conditions)

- Raw Material

- Epoxy Resin and Polyamine Hardener

- CAS No

- 25068-38-6 (Epoxy Resin Component)

- Thickness

- 15 mm (customizable)

- Application

- Industrial and Commercial Flooring

- Color

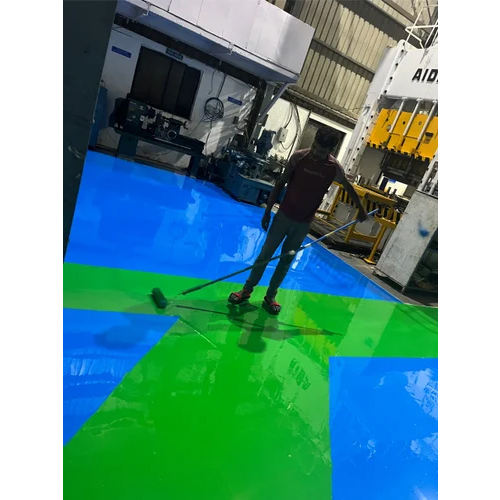

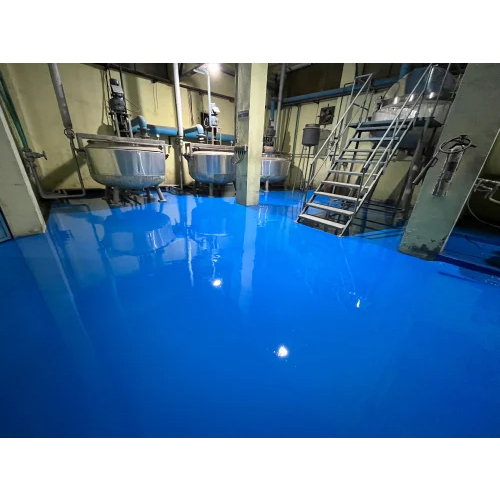

- Available in Multiple Shades (Grey, Green, Blue, etc.)

- Touch Dry

- 24 hours at 25C

- Total dry time

- 2448 hours

- Color Retention

- Excellent, UV Stable Grades Available

- Product Type

- Self Leveling Epoxy Flooring

- Compressive Strength

- 70 N/mm

- EINECS No

- 500-033-5

- Properties

- Seamless, Smooth, Glossy Finish, Self-Leveling, Non-porous, High Mechanical Strength

- Application Method

- Trowel/Spreader or Roller

- Resistant Feature

- Excellent Resistance to Chemicals, Abrasion and Impact

- Mix Ratio

- Base : Hardener = 2:1 by weight

- Storage Conditions

- Cool, Dry Place Below 30C

- Flexural Strength

- > 30 N/mm

- Bonding Strength

- > 1.5 MPa (for concrete)

- Pot Life

- 2540 minutes at 25C

- Curing Time for Heavy Duty Use

- 35 days

- Shelf Life

- 12 months in original sealed container

- Curing Time for Foot Traffic

- 24 hours

- VOC Content

- Low (<50 g/L)

- Water Absorption

- <0.1% (24 hours)

About Self Leveling Epoxy Flooring

Versatile Use and Applications

Self Leveling Epoxy Flooring is ideally suited for industrial and commercial environments, frequently used by facility managers, contractors, and businesses seeking dependable, seamless flooring. Used as a durable, non-porous, and glossy surface, it resists chemical, abrasion, and impact damage, making it perfect for warehouses, showrooms, factories, and laboratories. Available in customizable thicknesses and various colors, its application adapts precisely to your operational and aesthetic requirements for superior performance and appearance.

Payment Terms and Domestic Market Details

This product is primarily marketed across key domestic mar regions of India, contributing to its substantial market value. Rates are determined competitively, with personalized quotations provided based on project specifications and order size. The main domestic market covers major industrial zones, with convenient FOB port options to streamline delivery processes. Secure and flexible payment terms are available, ensuring ease and reliability for every procurement and supply operation.

FAQ's of Self Leveling Epoxy Flooring:

Q: How is self leveling epoxy flooring applied?

A: Self leveling epoxy flooring is typically applied using a trowel, spreader, or roller on a prepared substrate, where it levels itself to create a smooth, seamless finish.Q: What are the main benefits of using self leveling epoxy flooring?

A: The main benefits include high mechanical strength, excellent chemical and abrasion resistance, superior bonding to concrete, easy cleaning, vivid color options, and long-term durability.Q: When can the floor be used after application?

A: Foot traffic is possible after 24 hours of curing at 25C, while heavy-duty use is recommended after 3-5 days for optimal performance.Q: Where is self leveling epoxy flooring most commonly used?

A: This flooring is most commonly used in industrial settings, warehouses, commercial spaces, laboratories, and manufacturing units due to its resilience and easy maintenance.Q: What payment options are available for purchasing this product?

A: Flexible payment terms can be arranged, with competitive rates and quotations provided according to the scale of the purchase and project needs.Q: How long will the finished epoxy floor last in service?

A: Depending on environmental and operational conditions, self leveling epoxy floors typically provide a reliable service period of 5-10 years.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Epoxy Flooring Service Category

8 MM Epoxy Flooring Service

Price 160.0 INR / Square Foot

Minimum Order Quantity : 2000 Square Foots

Application : Manual

Color : Gray

Total dry time : 12 Hours

Hard dry time : 24 Hours

1 MM Epoxy Flooring Service

Application : Industrial, Commercial, Warehouses, Garages, Hospitals, Pharma, Parking Areas

Color : Gray, Green, Blue, Customized

Total dry time : 24 Hours

Hard dry time : 7 Days

10 MM Epoxy Flooring Service

Application : Industrial, Commercial, Warehouse, Garage, Hospitals, Laboratories

Color : Grey, Green, Blue, Custom

Total dry time : 1224 hours

Hard dry time : 24 hours

Abrasion Resistant Epoxy Flooring Service

Application : Industrial, Commercial, Garages, Warehouses, Manufacturing Areas

Color : Grey, Green, Blue, Customized shades available

Total dry time : 24 to 48 hours

Hard dry time : 7 days

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese