Abrasion Resistant Epoxy Flooring Service

Abrasion Resistant Epoxy Flooring Service Specification

- Raw Material

- Epoxy Resin, Polyamine Hardener

- Solid Content

- > 95%

- Properties

- High abrasion resistance, chemical resistance, seamless finish

- Resistant Feature

- Resistant to chemicals, oils, solvents, heavy traffic

- Color Retention

- Excellent

- Product Type

- Abrasion Resistant Epoxy Flooring Service

- Service Period

- 5 to 10 years depending on traffic and maintenance

- Application

- Industrial, Commercial, Garages, Warehouses, Manufacturing Areas

- State

- Liquid (before application), Solid (after curing)

- Thickness

- 1 mm to 5 mm

- Color

- Grey, Green, Blue, Customized shades available

- Hard dry time

- 7 days

- Touch Dry

- 2 to 4 hours at 30C

- Total dry time

- 24 to 48 hours

- Compressive Strength

- 60-90 MPa

- Application Method

- Trowel, Roller, Squeegee

- Substrate

- Concrete, Metal, Cement screeds

- Maintenance

- Easy to clean, low maintenance requirements

- Bond Strength

- > 2.5 MPa

- Adhesion Strength

- > 1.5 N/mm

- Surface Preparation

- Grinding, shot blasting, acid etching as required

- Shelf Life

- 12 months in unopened packaging

- Finish

- Glossy or Semi-glossy

- Temperature Resistance

- Up to 80C continuous exposure

- Odor

- Low odor during application

- Curing Time

- Full mechanical strength in 7 days

- VOC Content

- Low VOC, eco-friendly formulation

- Slip Resistance

- Available as per R9R12 DIN standards

About Abrasion Resistant Epoxy Flooring Service

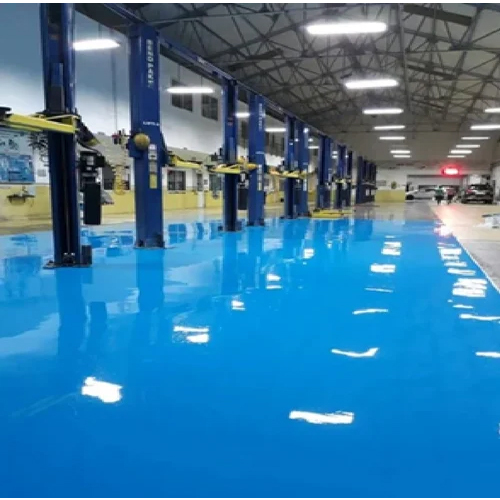

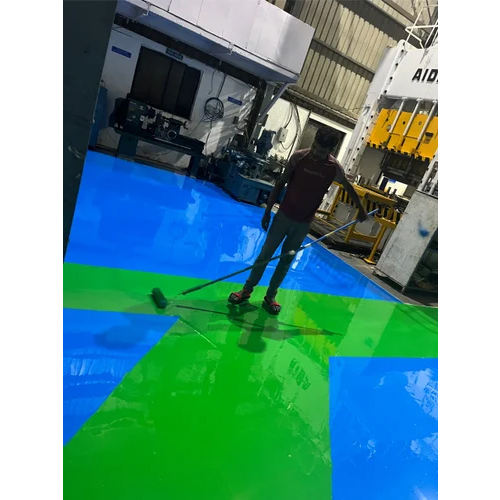

Optimum Application Surfaces and High-Performance Use

Our Abrasion Resistant Epoxy Flooring Service is designed for concrete, metal, and cement screeds, making it ideal for manufacturing plants, commercial areas, garages, and warehouses. Each application utilizes advanced machines and tools-including grinding, shot blasting, and acid etching-to deliver a kingly, seamless surface. Whether using a trowel, roller, or squeegee, we ensure consistent thickness and a striking, high-gloss or semi-gloss finish that is both durable and visually appealing for intensive use environments.

Certifications, Samples & Efficient Order Fulfillment

Distinguished for quality, our epoxy flooring solutions hold industry certifications to assure clients of reliable performance. Samples are available for evaluation prior to commitment, allowing informed expenditure decisions. We offer flexible FOB ports across India, facilitating swift transportation and logistics arrangements. Our team ensures order completion within promised timelines, offering comprehensive support from inquiry through installation for cost-effective, long-lasting flooring results in your facility.

FAQ's of Abrasion Resistant Epoxy Flooring Service:

Q: How does abrasion resistant epoxy flooring benefit industrial and commercial spaces?

A: This flooring offers superior durability, chemical resistance, and a seamless finish, making it ideal for spaces exposed to heavy traffic, machinery, and frequent cleaning. Its glossy or semi-glossy surface enhances both safety and aesthetics while reducing long-term maintenance costs.Q: What substrates can the epoxy flooring be applied to?

A: Our abrasion resistant epoxy flooring is suitable for application on concrete, metal, and cement screeds, ensuring optimum adhesion and performance across a variety of industrial and commercial settings.Q: What is the typical curing and drying time for this service?

A: The surface will become touch dry within 2 to 4 hours at 30C, with a total dry time of 24 to 48 hours. Full mechanical strength and a hard dry finish are achieved in 7 days, ensuring longevity and durability.Q: Where is this flooring service commonly used?

A: It is widely featured in manufacturing facilities, warehouses, garages, and commercial spaces requiring kingly abrasion resistance, easy maintenance, and slip-resistant safety standards.Q: What is involved in the surface preparation process?

A: Surface preparation includes grinding, shot blasting, or acid etching as required, ensuring an optimal bond between the substrate and the epoxy, resulting in distinguished adhesion and finish quality.Q: How cost-effective is this epoxy flooring solution?

A: Our service is offered at a special rate, balancing initial expenditure with an extended service period of 5 to 10 years, low maintenance requirements, and reduced need for repair, making it an optimum and cost-effective long-term investment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Epoxy Flooring Service Category

8 MM Epoxy Flooring Service

Minimum Order Quantity : 2000 Square Foots

Raw Material : Epoxy Resin, Hardener

Solid Content : 100%

Properties : Highly Durable, Abrasion Resistant, Chemical Resistant

Resistant Feature : Chemical, Oil, Wear, Impact

Color Retention : Excellent

1 MM Epoxy Flooring Service

Raw Material : Epoxy Resin & Hardener

Solid Content : 100%

Properties : Seamless, High Gloss, Antiskid, Dustproof

Resistant Feature : Abrasion, Chemicals, Oil, Water, Stain

Color Retention : Excellent

4 MM Industrial Epoxy Flooring Service

Minimum Order Quantity : 2000 Square Foots

Raw Material : Epoxy Resin and Hardener

Solid Content : 98%

Properties : High impact resistance, seamless finish, nondusting

Resistant Feature : Chemical, abrasion, water, oil, and stain resistant

Color Retention : Excellent

Self Leveling Epoxy Flooring

Raw Material : Epoxy Resin and Polyamine Hardener

Solid Content : 98% 2%

Properties : Seamless, Smooth, Glossy Finish, SelfLeveling, Nonporous, High Mechanical Strength

Resistant Feature : Excellent Resistance to Chemicals, Abrasion and Impact

Color Retention : Excellent, UV Stable Grades Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese