8 MM Epoxy Flooring Service

Price 160.0 INR/ Square Foot

8 MM Epoxy Flooring Service Specification

- Touch Dry

- 8 hours

- Color

- Gray

- Raw Material

- Epoxy Resin, Hardener

- Resistant Feature

- Chemical, Oil, Wear, Impact

- Properties

- Highly Durable, Abrasion Resistant, Chemical Resistant

- Solid Content

- 100%

- Application

- Manual

- Application Method

- Trowel / Roller / Brush

- Thickness

- 8 Millimeter (mm)

- Total dry time

- 12 Hours

- Compressive Strength

- >70 MPa

- Color Retention

- Excellent

- CAS No

- 25068-38-6

- Hard dry time

- 24 Hours

- Product Type

- Epoxy Flooring Service

- Service Period

- Up to 10 Years

- EINECS No

- 500-033-5

- State

- Liquid to solid after curing

- Storage Conditions

- Cool, dry place, away from direct sunlight

- Water Absorption

- <0.10%

- Curing Time (Full traffic)

- 72 hours

- Curing Time (Foot traffic)

- 24 hours

- Adhesion to Concrete

- Excellent

- VOC Content

- Low / Compliant

- Gloss Level

- Glossy / Semi-gloss

- Slip Resistance

- Customizable

- Bond Strength

- >1.5 N/mm

- Shelf Life

- 12 months (unopened)

- Surface Preparation

- Diamond Grinding / Shot Blasting

- Packaging Size

- Custom / On demand

8 MM Epoxy Flooring Service Trade Information

- Minimum Order Quantity

- 2000 Square Foots

- Delivery Time

- 3 Days

About 8 MM Epoxy Flooring Service

Superior Durability & Performance

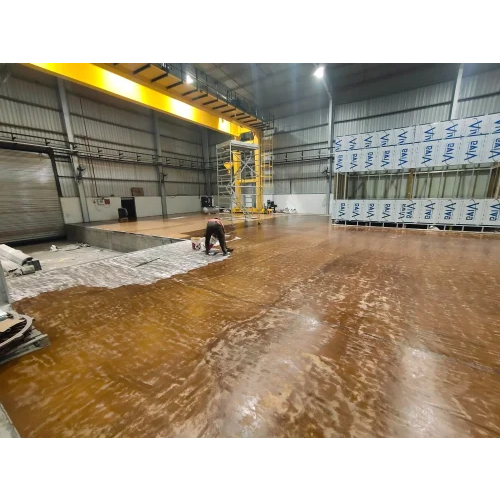

Our 8 MM Epoxy Flooring is engineered for exceptional durability and robustness. It resists chemicals, oil, wear, and impact while maintaining its appearance and integrity over time. With abrasion and chemical resistance, it stands up to heavy-duty environments, making it ideal for manufacturing, warehouses, and commercial spaces.

Expert Surface Preparation

The flooring application begins with thorough diamond grinding or shot blasting, ensuring the concrete surface is impeccably prepared for epoxy adhesion. This process is vital for achieving maximum bond strength and a flawless, seamless finished floor that holds up under demanding operational conditions.

Customizable & Efficient Application

Choose from glossy or semi-gloss finishes and variable slip resistance levels to suit your preferences or safety requirements. Our skilled technicians apply the system manually using trowels, rollers, or brushes, allowing complete control and customization for every project, no matter the size.

FAQ's of 8 MM Epoxy Flooring Service:

Q: How is the surface prepared before applying the 8 MM Epoxy Flooring?

A: The surface is meticulously prepared using diamond grinding or shot blasting to remove contaminants and create the right texture, ensuring excellent adhesion and longevity of the epoxy flooring.Q: What is the recommended curing time before using the floor for foot and vehicle traffic?

A: Foot traffic can resume 24 hours after installation, while full, heavy traffic is recommended after 72 hours to allow the epoxy to completely cure and reach maximum strength.Q: Where can this epoxy flooring system be installed?

A: This flooring is suitable for industrial plants, warehouses, garages, commercial kitchens, and anywhere demanding high durability, chemical, and abrasion resistance.Q: What benefits does this epoxy flooring provide over regular flooring solutions?

A: It offers high compressive strength, excellent chemical and abrasion resistance, customizable slip resistance, low VOC emissions, superb color retention, and a service period of up to 10 years, making it both cost-effective and reliable.Q: How often does this flooring need maintenance?

A: Routine cleaning is usually sufficient; due to its highly durable and chemical-resistant surface, this flooring generally requires little maintenance over its service life.Q: What is the process of applying this epoxy flooring system?

A: After surface preparation, the epoxy resin and hardener are mixed and manually applied via trowel, roller, or brush. The floor transitions from liquid to solid within the curing period, with touch dry at 8 hours and full dry at 12 hours.Q: What packaging sizes are available for the epoxy system?

A: Packaging can be customized according to project requirements and demand, making it convenient for applications of any scale.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Epoxy Flooring Service Category

5 MM Industrial Epoxy Flooring Service

Hard dry time : 7 Days

Application : Industrial Flooring (Factories, Warehouses, Garages)

Color : Grey, Green, Blue, Customized

Total dry time : 24 Hours

1 MM Industrial Epoxy Flooring Service

Hard dry time : 68 hours

Application : Industrial Flooring, Warehouse & Factory Flooring

Color : Grey (custom colors available on request)

Total dry time : 24 hours at 25C

2 MM Epoxy Flooring Service

Hard dry time : 24 Hours

Application : Industrial, Commercial, Warehouses, Garages

Color : Green, Grey, Blue (Customizable)

Total dry time : 24 Hours

3 MM Industrial Epoxy Flooring Service

Hard dry time : 2448 hours

Application : Warehouses, Factories, Garages, Industrial Plants

Color : Grey, Green, Blue, Red, Custom shades

Total dry time : 24 hours at 30C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese